01.Product Information

Comprehensive documentation of parts information: materials, properties, attachments, arrival time, processing route, etc.

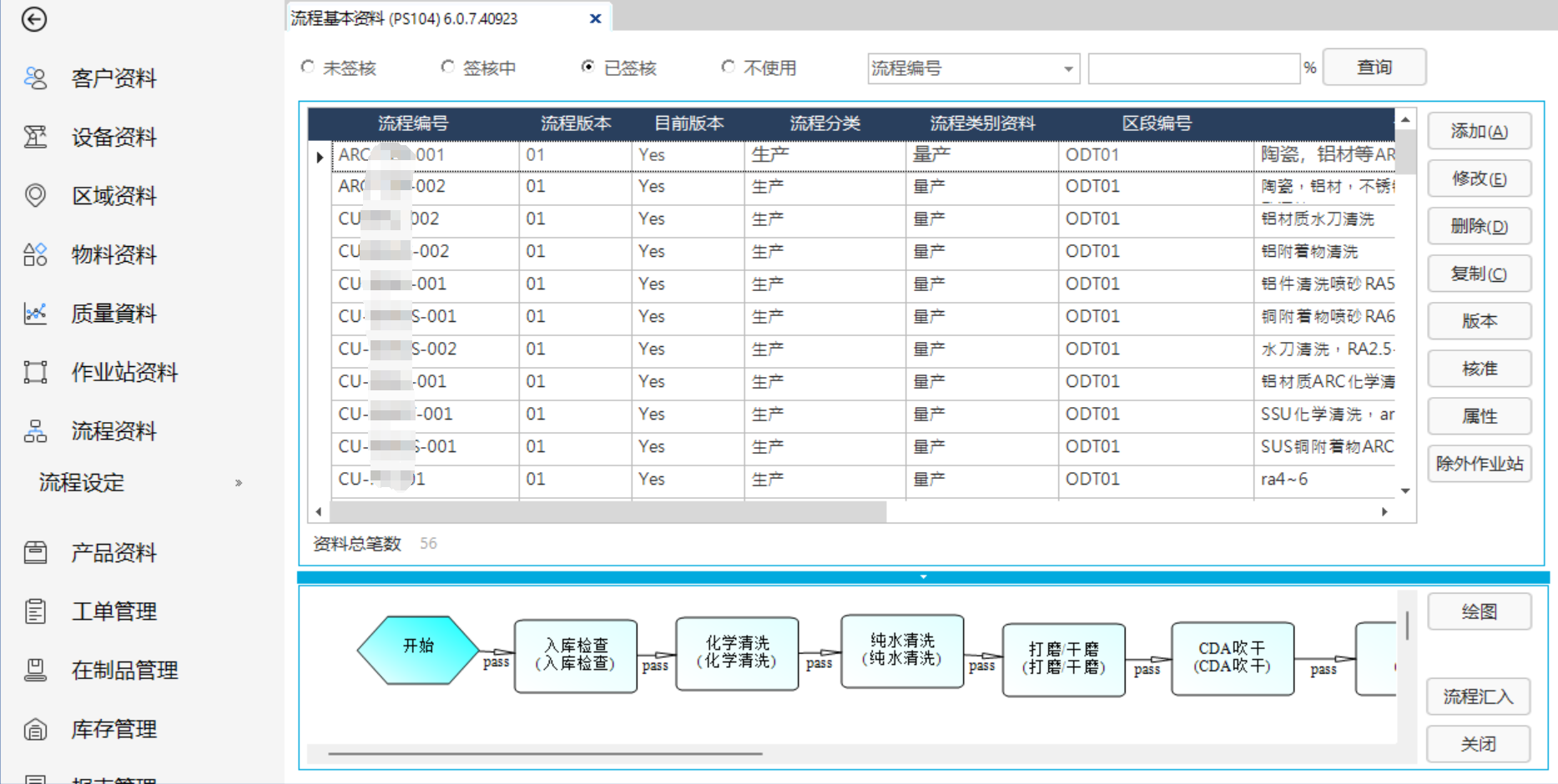

02.Process Setup

Workstations are consolidated into process flows, with defined operational parameters, SOPs, and technical guidance.

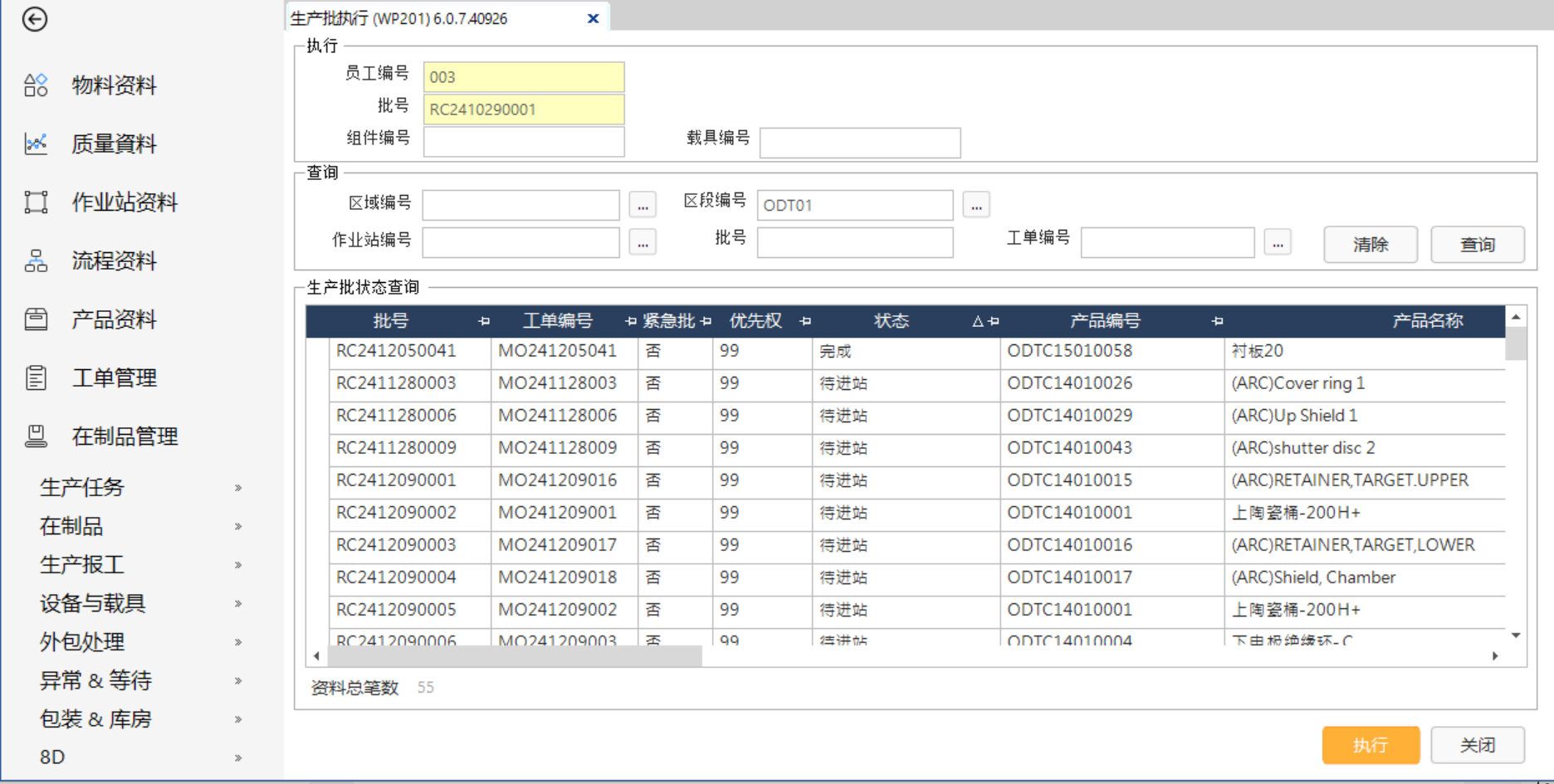

03.Production Management

Accurately record entry and exit times, work cycles, operator information, and machine information.

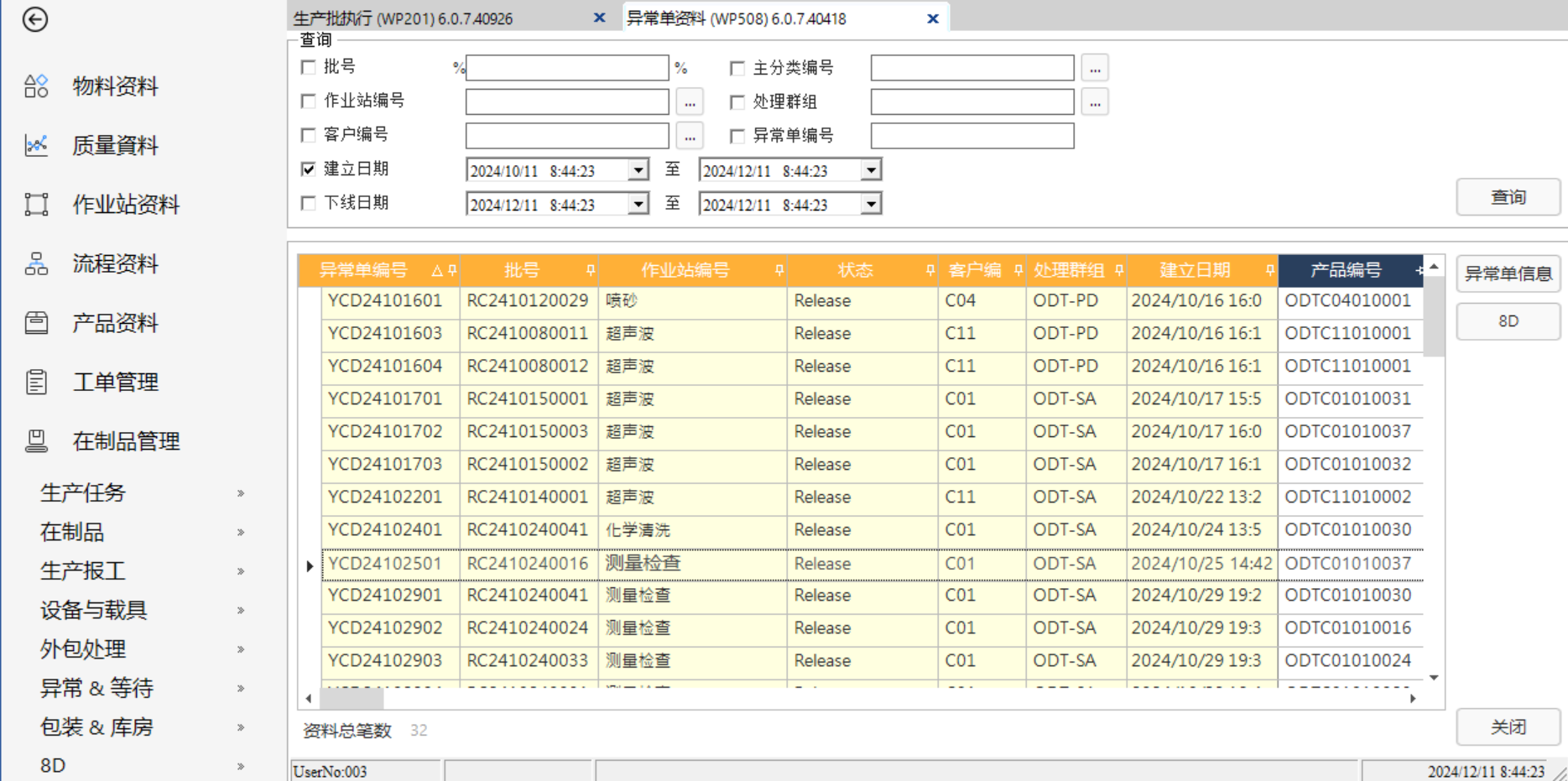

04.Exception Handling

Cross-functional oversight of parts anomalies ensures immediate resolution and customer feedback.